Air Compressors for the Plumbing Industry

When a plumber shops for an air compressor, he or she undertakes an important decision that affects how work gets done. No matter what range of work a plumber does, his or her air compressor powers an integral part of the job.

Air compressors for plumbers vary widely in size, type and capacity, ranging from huge models that fit into a small room to ones you can easily carry or roll around. It makes sense that air-compressor selection warrants a bit of research, evaluation and consideration for decision making.

An air compressor squeezes air into a smaller space to concentrate it and create pressure. When a machine compresses the air, it goes below atmospheric pressure and will work to escape, which creates energy.

The compression is either isothermal or adiabatic. Isothermal compression involves perfectly cooling of the air so it remains a consistent temperature, while adiabatic compression heats the air as it’s compressed. The heat of adiabatic compression builds pressure faster and delivers more force throughout the process. However, it requires more input work to achieve the same output. New and innovative cooling technology continues to emerge and emulate the isothermal process.

Any air compressor for plumbing will usually have an electric internal motor with a v-belt or direct drive. Compressors with an internal-combustion engine that runs on gas or diesel could also have a gearbox, v-belt or direct drive. Most air compressors come completely assembled as a whole unit.

Compressor Classification and Types

The various types of air compressors fall into one of two categories, positive displacement or dynamic. Generally, positive displacement is most common and gives constant volume with variable pressure as well as broad discharge options while dynamic delivers constant discharge pressure and a range of volumes/capacities.

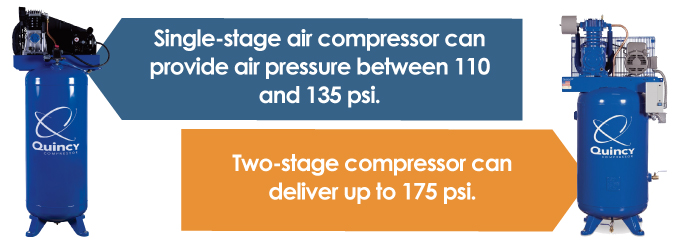

Many compressors you see will be single stage, two-stage or multi-stage, which generally refers to the number of steps the compressor takes to deliver the air pressure you need. Depending on the model, a single-stage air compressor can provide a pressure between 110 and 135 psi, while a two-stage compressor can deliver up to 175 psi.

There are six, main types of air compressor:

Centrifugal:

These dynamic machines contain an impeller that delivers kinetic power using centrifugal force, accelerating the velocity of air as it goes through each impeller. A diffuser then slows down the air and converts the kinetic power into potential power. A centrifugal compressor will normally produce large volumes of low-pressure air. It requires less space but more power than a comparable reciprocating unit.

Liquid-Sealed Rotary Screw:

A ring of water does the work in this compressor that a piston or vane does in other compressors. As the rotary ring turns, water comes in constantly, cooling and cleaning the air plus taking out some of its humidity as it circles the chamber. These systems remove all the water from the pressurized air. They come in single-lobe models, suitable for low-pressure needs in the range of 5-15 psi, or with a double lobe that would be sufficient for higher-pressure needs in the range of 50-100 psi. This compressor offers a range of power and volume options but of course requires a water source.

Reciprocating Piston:

In this compressor type, a piston generates the energy that compresses the air. They range from 1-30 horsepower, and usually the smaller compressors have one piston, but they can have two or even more. This positive-displacement machine may have a single-acting chamber or a double-acting chamber; a single compresses air at one end of the chamber and piston, while a double compresses air at both ends of the piston and chamber. You will encounter water-cooled and air-cooled models, Water is generally more effective and uses less power, but initial and operating costs are high. The reciprocating-piston compressor gives the advantage of affordability and low operating costs, but the disadvantage of being somewhat noisy.

Rotary Screw:

Two helical screws, or rotors, trap air between them and turn in opposition to generate the energy that compresses the air. The rotary-screw compressors are common, reliable, workhorses of industry. Though you can find oil-free models, the oil-flooded feature helps cool the machine. This compressor is praised for its compact design and ability for continuous operation.

Scroll:

Two spiral elements, one stationary and one in eccentric motion, trap air and force it to the center of a spiral. This type of compressor is small, and operates quietly, but has low capacity. It can be a good choice for smaller jobs.

Sliding vane:

The vanes, affixed into a cylinder-shaped housing, slide back and forth in grooves and held in place by centrifugal force as the rotor turns. This type progressively compresses the air. The sliding vain gets high marks for compact size and shape, as well as its capability for low-horsepower jobs. It operates efficiently, but some argue not as well as a reciprocating compressor.

Compressor Capacity

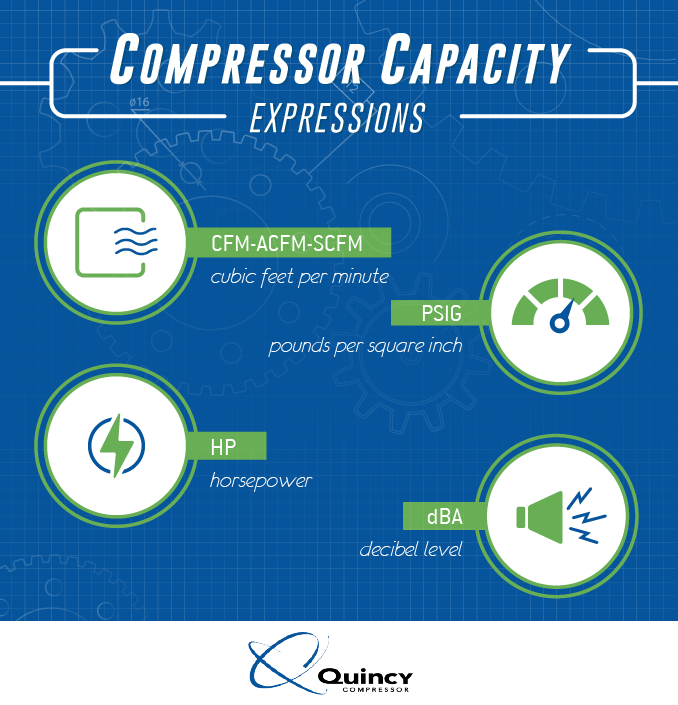

An air compressor’s production-output potential is typically expressed using four main expressions, and most experts agree on their order of importance:

- CFM-ACFM-SCFM is cubic feet per minute and is the measure of how much air a compressor can produce.

- PSIG is pounds per square inch gauge and is a unit of pressure relative to the atmosphere.

- HP, the most common specification, is horsepower. Unfortunately, HP is not an accurate measure of how much air the compressor can produce.

- dBA is the decibel level, and gives you a measurement of how loudly the compressor will operate.

You can achieve maximum efficiency by finding a suitable machine that produces the most CFM using the least HP and with as little dBA as possible.

Compressor Duty

Duty refers to the amount of work you need the compressor to do. For this purpose, machines come in classes of light, medium and heavy duty. For examples:

A light-duty compressor might run for several hours a day, perhaps a single-stage, air-cooled would be typical in this category. The general expectation for a medium-duty compressor is that it will operate for 10 hours daily. If you need a compressor that can run up to 24 hours each day, seek one with a heavy-duty rating.

Compressor Considerations

You’ll see by the sheer number of air compressors for plumbing how many options and choices you have in shopping for one. You can narrow down your choices by evaluating your needs:

- Budget: Calculate how much you have to spend on a compressor based on the perspective that it is a capital expense, as well as an investment that will last for many years. Consider your quality and production goals, as well as operating costs and allow those to factor into your decision on how much to spend on a compressor and what kind to buy.

- Load: Think about how you will expect the machine to perform, for example if it will run all day every day, regularly but not constantly or occasionally. You might need one that handles any kind of load any day. You’ll have options within different compressor models for continuous or intermittent operation, as well as different duty cycles, regulators and other variations.

- Needs: Gauge your capacity needs by checking the requirements of the equipment you have and use now, as well as anything you might get in the future during the life of the compressor. Also, consider if you ever borrow or rent any tools you will plug into the compressor.

- Noise: Everyone’s noise tolerance is different, and some types are perceived as quieter than others. Noise level may not affect your decision at all, or it might make a big difference based on your specific work environments and preferences.

- Oil: Many types of air compressors are available in an oil-free version, some of which have no instance of oil in the air stream, while others employ filtration to achieve a clean delivery. Some users want the oil since they can be more durable, but others need a completely oil-free operation for specific manufacturing processes.

- Piping: The choice comes down to steel or plastic, and there are many strong arguments for either. Steel is stronger, more durable and lasts longer, but it is the costlier option of the two. Plastic is light, easy to cut and manageable, but people complain about some pressure loss in plastic piping. Another choice that may dictate piping is the proximity of the compressor. If it is a few feet away, you can probably have smaller-diameter piping than if the compressor is a few hundred feet away. Some experts advise that plumbers err on the larger side with piping diameter to ensure can-do capacity for whatever you encounter.

- Portability: Do you need to be able to easily load and transport your compressor, or can you feasibly have it affixed to the truck or in the shop and use it that way? Some plumbers have a permanently attached, large capacity compressor at the shop, a mobile unit on board the vehicle and a small model they can carry into homes or businesses with them. Consider how you’ll use yours before making a decision.

- Regulation: This is basic control of air flow from your compressor and is an important consideration, since the range of the regulator ability determines what tools you will be able to power or not. For example, some plumbers may only need to run small tools from the compressor occasionally while others need maximum power constantly. The objective of course is to have a regulator that adjusts to the task, and that might be one that has constant-speed control or a start-stop configuration. Compressors can have dual controls, which gives plumbers the flexibility to use the machine a number of ways. There are also options for sequenced setups that allow for switching back and forth between different compressors designed for different uses and capacities.

- Space: Evaluate the room you have to operate a compressor, especially ventilation space, and include considerations for whether it will sit at the shop, in the truck or be something you carry with you. Think about the spaces where you usually work and consider any special needs that might exist or justify one purchase over another. It could be that you need several sizes to accommodate the different jobs you do.

- Temperature: Do you work in extremely hot or cold weather? Temperatures are worth considering since they can affect nearly any or all operations. Your typical temperature range can become a selection factor and help you eliminate choices not rated to perform as you need.

- Versatility: How flexible does the compressor need to be? Will you want to use it for business and at home for bike tires and other duties? What range of equipment will it need to power? These are important questions to ask yourself.

Compressor Accessories

Whatever your choice of compressor, there are a number of accessories that can help you ensure safe and efficient operation. For example, an air-receiver (storage) tank can prevent your compressor from working constantly. A belt guard is mandatory for all v-belt compressors or those using a flywheel, motor pulley or belt and protects against contact with belts on both sides.

Diagnostic controls will help you keep a watchful eye on compressor function as you monitor things like pressure, temperature and other operational mechanics. An intake filter helps clean the air by removing fine particulate matter at the point of the intake suction valve. Magnetic and manual starters are available to offer protection from thermal overload.

Compressor Care & Service

An air compressor for plumbing needs regular inspection and maintenance so that you get the best value for your money with the longest possible life of your compressor. You can keep your compressor in peak condition by following these steps:

- Monitor temperatures, especially in a water-cooled system

- Add more oil in hot weather since the compressor works harder in heat

- Ventilate the compressor properly

- Drain the tank after every use

- Check drain valves of an air-cooled system

- Inspect regularly for leaks, excessive dirt and clogged filters or piping.

Expected compressor life depends a lot on what kind you buy and if its capacity is well-matched to the demands placed upon it, but for example, an average rotary-screw compressor could work almost constantly and give about 40,000 hours of operation. Naturally, good care extends compressor life, while things such as overload or lack of maintenance, are likely to shorten its life.

Quincy Compressor provides a full range of air-compressor solutions for plumbers and many other industries. We can help with new systems, green technology, air-treatment options, and establishing an energy-efficient quotient. Our network of factory-trained service personnel also provide regular maintenance, service, parts and expert information.

We offer air compressors from the low horsepower and small pressure ranges to large horsepower and high pressure ranges, as well as an extensive line of options for controlling the air according to your environmental needs. For example, Quincy Compressor offers cycling and non-cycling refrigerated dryers, oil-free compressors, air-filtration items and technology to manage condensation. Among our green alternatives are natural-gas powered compressors.

You will find 24-7 support through qualified dealers and a wealth of information in the Knowledge Center of the Quincy Compressor website, where case studies and white papers contain real-world examples. You gain additional peace of mind with our innovative, long-term, extended warranty programs, too. Quincy has 200 locations worldwide so you can find what you need and get to know the compressed-air experts in your area. Find a dealer near you today!

Our company began in 1920 with a trio of enterprising Illinois partners who found financial backing for their vacuum-pump machine, which mainly was used to milk cows. As the demand for compressed air grew, Quincy also grew and evolved to become a leading expert in the industry and earned recognition as a leading compressed-air solutions provider.