The Evolution of Compressed Air — An Essential Element to Industry

Chapter 1: The Importance of Compressed Air Systems in the Modern Industrial Age

In ancient times, the earliest forms of compressed air didn’t come from complex machines. Human beings used their lungs to blow air onto hot embers, stoking the flames of a growing fire, which was an essential part of the earliest forms of civilization. Fire played a large role in skilled labor, but creating an inferno hot enough to melt and cast the precious metals of the day became a challenge that needed a much more powerful compressed air source than could be delivered by the human lungs.

Skilled craftsmen created low-pressure devices that were powered by hands and feet, and eventually even by the water wheel, to create a fire hot enough to melt early metals. The famous hand-operated bellows of antiquity helped with the melting and casting of copper, gold, lead and tin, but more powerful compressed air systems were still needed to accomplish the feats that came with the industrial revolution.

Following the development of some of the earlier mechanical compressors in the 17th century, which still used traditional piston and cylinder mechanisms that dated back to the time of the Romans, came the onset of screw compressor systems. As the systems improved and evolved with more powerful motors and the use of electricity, compressed air further established itself as an essential staple in manufacturing and in the technological advancements of the 20th century.

Since then, compressed air systems have become more complex. They’re now essential components in the modern industrial world. Today, everyone from the farmers working in the vast, rural countryside to the people constructing the automobiles we drive every day utilize compressed air systems. Medical equipment and pharmaceutical industries, the energy industry and manufacturing facilities all utilize compressed air in their daily operations to produce the many goods and services we have become accustomed to.

Air remains one of the most commonly used and available resources in modern business, but it requires a great deal of energy to produce.

When looking at air compressors by industry, and how the systems are used, understanding their benefits can help you make a better decision on which type of compressor is right for your business needs. Compressed air systems range from smaller and more portable units to large-scale industrial pieces of equipment that can supply clean air to an entire facility.

Compressors also come in different models and can operate on different mechanical principles. Selecting the right compressed air system often depends on what application you’re looking for, and how you plan to use compressed air in your business.

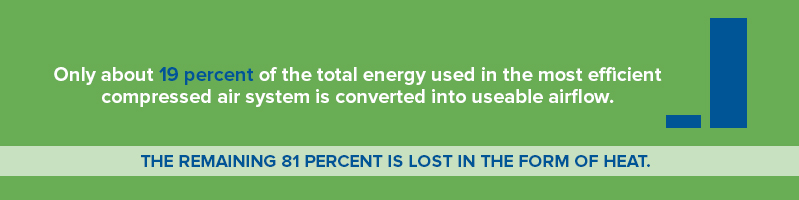

Compressed air is important because of its cleanliness and ease of use. Unfortunately, it’s also an expensive utility. Only about 19 percent of the total energy used in the most efficient compressed air system is converted into useable airflow. The remaining 81 percent is lost in the form of heat, which is why maintaining and selecting the best system for your business is so important. Not fixing air leaks, or using compressed air when other cheaper alternatives exist, can cost you money in the long run, and it can cut into resources that could be better spent on other business needs.

If you’re interested in employing compressed air at your company to improve productivity or efficiency, or even bolster the performance of an outdated system, explore this guide, which features the history of compressed air use in industrial development, how compressors operate and which methods are employed today for industries including woodworking, natural gas, automotive, agriculture, medical and manufacturing.

Chapter 1: The History of Industrial Compressed Air Systems

The earliest forms of compressed air tools, which date as far back as 2000 B.C., were bellows to smelt and forge the ores needed for metal working, powered by human energy or water wheels. Bellows are still common today to fan the flames of wood burning fireplaces in some homes, which in turn supplies the needed oxygen to increase the heat of the fire.

A typical fire could obtain the melting point of certain metals, but the increased demand for more heat and compressed air created stronger alloys, as well as the need to work with more difficult ores. Increasing the amount of oxygen in industrial fires through early compressed air systems, ancient people created stronger metals than what could be found naturally in the earth, which helped pioneer the field of metallurgy.

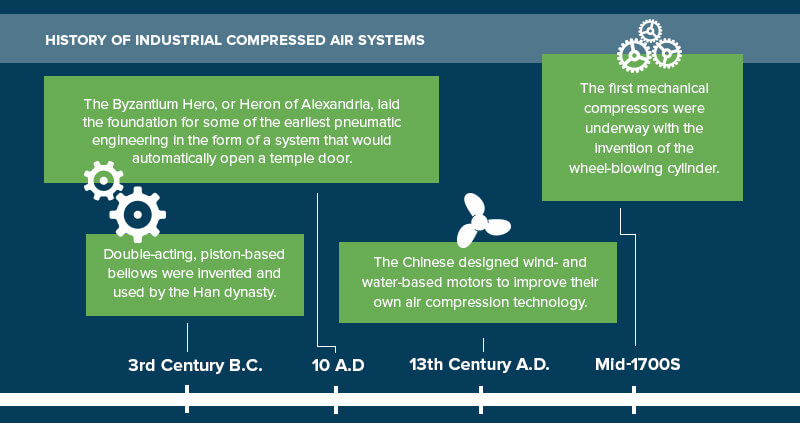

Early industrial air compressors were low-pressure systems. These systems improved throughout the centuries. In ancient China around the third century B.C., double-acting, piston-based bellows were invented and used by the Han dynasty. In 10 A.D., the Byzantium Hero, or Heron of Alexandria, laid the foundation for some of the earliest pneumatic engineering in the form of a system that would automatically open a temple door. Around the world, developments continued, even though many of the world’s peoples were separated by oceans and vast distances. By the 13th Century A.D., the Chinese designed wind- and water-based motors to improve their own air compression technology.

Advancement was slow, but by the mid-1700s, the first mechanical compressors were underway with the invention of the wheel-blowing cylinder, pioneered by a man named John Smeaton in 1762. Smeaton was an English engineer, and he created a new mechanical system that slowly replaced the traditional bellows of the day. The wheel-blowing cylinder was revolutionary at the time, and it can be called the earliest mechanical compressor in human history.

Although Smeaton’s advancement was an efficient system, it would soon be replaced by another invention in 1776. English engineer and inventor John Wilkinson created the superior blasting-machine, an invention that would lay the foundation for all mechanical compressors that followed.

Going beyond just metallurgy, the demand for compressed air in the late 1700s had now branched out into several more industries, including mining, which demanded the ventilation of the subterranean areas. Wilkinson’s invention is considered a prototype for all mechanical compressor systems, but at the time, experiments with vacuum-based systems were also being conducted. By 1799, Englishman George Medhurst invented the first motorized air compression system that was used primarily in the mining industry. Medhurst’s engineering feats led to the first atmospheric railway, a compressed-air-powered rail system.

Throughout the 1800s, many more advancements became essential to compressed air systems. In the industrial age, compressed air also became a means to transport energy. Hydraulic systems also advanced. As the demand for specialization in compressed air use increased, which included the need for different pressures and the use of electric motors, the technology diverged.

The divergence in engineering throughout the 19th and early 20th centuries provided the groundwork for the three most common types of modern compressor systems found in the industry today.

Table of Contents

- The Evolution of Compressed Air — An Essential Element to Industry

- Chapter 8 Conclusion: Compressed Air Systems Utilized in Manufacturing

- Chapter 2: The Modern Industrial Compressed Air System

- Chapter 4: Natural Gas Industry and Compressed Air

- Chapter 3: Woodworking and Compressed Air

- Chapter 5: Compressed Air Systems for the Automotive Industry

- Chapter 6: Compressed Air Systems in Agricultural Use

- Chapter 7: Compressed Air in the Medical and Pharmaceutical Industries