Guide to DOE Compressed Air Systems Standards

Energy Efficiency Standards

The new energy efficiency standards set by the Department of Energy (DOE) will help consumers and business owners save energy, time and money. When an appliance or system is efficient, it uses the least amount of energy to perform a task. Benefits of energy efficiency which affect the country as a whole include:

- Conserves energy for use elsewhere

- Reduces energy bills

- Saves natural resources

- Controls pollution

Since the 1970s, the department has been working to enforce energy efficiency standards. In the 21st century, with an increased demand for efficient products, legislators continue to expand energy conservation standards.

For example, the Energy Policy Act of 2005 (EPAct), which addresses energy efficiency as well as other topics relating to energy production, set new standards for 16 products. Then, in 2007, the Energy Independence and Security Act (EISA) established new or updated standards for 13 products and also required the department to review and update all standards and test procedures regularly. In 2016, the department issued a pre-publication final rule for compressed air standards. Finally, in 2017, the department published a final rule in the Federal Register for air compressor test procedures – all of which we’ll discuss in this guide.

Air compressors are valuable cost-saving pieces of equipment used in all types of industries. If you work in an industry that uses air compressors, it helps to know the energy efficiency requirements and what to expect in the near future. If you seek information about the department’s compressed air standards, we put this guide together to answer your questions and keep you informed. In this guide we’ll cover the following topics:

- What the DOE standards are

- How these standards came to be

- How DOE energy efficiency requirements impact the air compressor industry

- How the DOE standards have changed

- How to achieve compliance with the DOE energy efficiency program

To most consumers, energy efficiency is important. Energy-efficient appliances and equipment cut energy bills and make less of an environmental impact. At Quincy Compressor, we are proud to meet DOE standards and offer customers efficient air compressors they can count on. We are excited to lead the way towards energy conservation for air compressor owners and others in the industry.

Chapter 1: What are the DOE Standards?

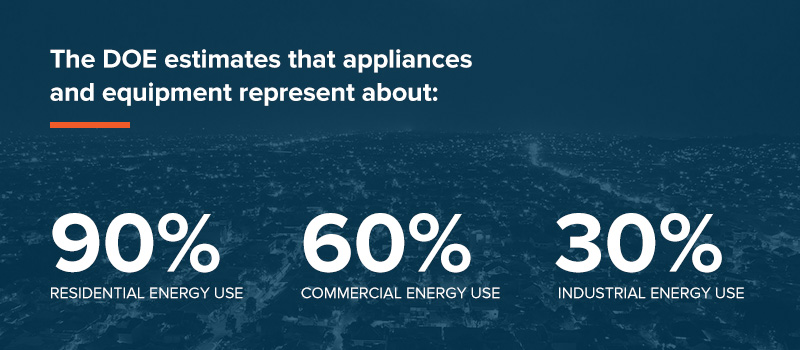

- The DOE sets minimum energy efficiency standards for about 60 categories of equipment and appliances used in homes and businesses.

- These standards save consumers billions of dollars every year without decreasing the capabilities of their products.

- For products purchased through 2035, Americans will save $2.4 trillion due to energy efficiency standards.

- The law mandates that all manufacturers and importers of covered products must use the DOE test procedure to ensure compliance.

How an Air Compressor Uses Energy

- Seventy-six percent of the lifetime cost of an air compressor is electricity.

- An air compressor uses an electric motor or gas engine to take in air at one condition and release air at an increased pressure to power a range of industrial or commercial equipment.

- Air compressors use about six percent of all motor-driven electricity in the industrial sector.

- Energy-efficient air compressors costs less to operate.

- The new standards established in 2016 set requirements for lubricated rotary compressors, not unlubricated rotary compressors or reciprocating compressors.

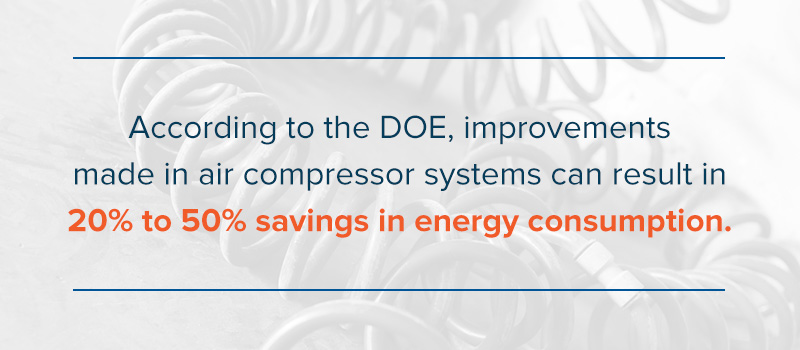

- The DOE estimates the new standards will save 0.16 quadrillion British thermal units (BTUs) by compressors sold over 30 years resulting in a savings of up to $400 million for compressors purchased.

- The standards will also prevent the emission of an estimated 8.2 million metric tons of carbon dioxide.

- The energy saved is equivalent to the annual electrical consumption of 1.3 million households, and the emissions are comparable to what 1.7 million cars put out per year.

The DOE Standards for Air Compressors

- The purpose of the standards is to improve the efficiency of electric motors and pumps to conserve energy resources.

- The standards are yet to be mandated, however, many air compressors manufacturers are already making improvements.

- The newly adopted standards are expressed in isentropic efficiency.

- Isentropic efficiency refers to the ratio of the theoretical isentropic power required for a compression process to the actual power required for the same process.

- Compressors must meet specific criteria to be tested by the DOE.

- These standards do not cover reciprocating compressors.

- To determine the standard level a compressor must meet, the correct equipment class must be identified.

- Compressor manufacturers have five years to bring their products into compliance.

- In the final rule published in the Federal Register, the DOE also establishes test methods to measure the inlet and discharge pressures, packaged compressor power input and actual volume flow rate as well as theoretical calculations – all required to calculate isentropic efficiency.

- Also established in the final rule are sampling plans requirements, representation requirements and enforcement provisions.

- Certain equipment is required during testing in specific environments.