Table of Contents

Air compressor fittings are critical to keeping your unit running efficiently and delivering the air power you require for your operations. Knowing the types of air compressor fittings available is essential to choosing the right components for your specific model. In addition, regularly changing your fittings and hose will keep your system running smoothly and keep you safe when using it. In this guide, we’ve detailed the different types of fittings, their benefits and how to choose the right ones for your air compressor.

With Quincy Compressor, you can keep your air compressor running smoothly.

What Are Air Compressor Fittings?

Air compressor fittings are attachments that maintain a consistent flow of air and pressure throughout the compressor. Each fitting has a different role, but they are all crucial to managing your unit’s health and functionality.

When it’s time to replace the fittings on your air compressor, start by checking the size you need. Most manufacturers follow the National Pipe Tapered (NPT), which refers to a fitting’s thread size. This sizing indicates which parts are compatible, so you already know which ones will fit before installing them. Using an NPT chart, you should measure and determine the size of your pipes for a fitting. You can source the various air compressor fittings you may need with that information.

Choosing the right size is crucial. If the fittings aren’t compatible, there will be a loose fit, which allows air to escape from your air hoses and connectors. When air escapes, it reduces your system’s efficiency and the pressure it can deliver. It’s worth taking time to understand the NPT chart and the different sizes for hoses and connectors to keep your air compressor working at its best.

The NPT chart is usually in inches and displays the threads per inch and the outside diameter of the pipe. Most manufacturers will advertise their parts to conform with the NPT chart.

There are three main air compressor fitting types to choose from.

Couplers

Couplers facilitate the connection of an air tank or air compressor to the air lines. When you disconnect the hose, the coupler also closes to seal in the air. Couplers come in a range of styles, including automotive, industrial, ARO and V-style.

There are two main types of couplers — automatic and manual. Automatic fittings allow you to plug in your air lines directly. They also quickly seal the air opening when the hose or male part is removed, allowing the O-ring or female connection to close completely. Manual couplers have a collar you must pull on to insert and remove the hose. Hold onto the hose tight as you remove it. It will shoot out as the compressed air pushes it out of the coupler.

Plugs

Couplers and plugs go together. Whichever style you choose for your coupler, you need the same style for the plug. The essential piece of information you need to decide on a plug is the flow size, or the volume of air the plug can manage. Most standard air compressors require a plug with a 1/2-inch or 1/4-inch flow size, with the latter being more common.

Just like couplers, plugs come in automotive, industrial, ARO and V-style designs. The style of fitting you choose comes down to personal preference, although automotive and industrial variants are more common and easier to find at chain hardware stores. Quality and fit are the most important factors when buying an air compressor plug, so opt for a brand with known quality to prevent compressed air leaks.

Connectors

Because there are so many different compressed air fitting types, manufacturers have come to recognize how difficult it can be to find the one you need. That’s why companies color-coordinate their couplers and plugs. For example, you may find a company that matches colors with the following classes:

- Red for Automotive

- Green for Industrial

- Blue for ARO

- Yellow for V-style

Why Are Air Compressor Fittings Important?

Compressed air is an important part of running your system. The air must flow well to power pneumatic tools or fill your bicycle tires with air. Compressed air fittings help the system run efficiently. With the right fittings, you can make use of high-pressure air without having to worry about leaks or damage. Even though these small parts look simple, they play a crucial role in directing the airflow and keeping your air compressor delivering the power you need.

What Are the Benefits of Air Hose Fittings?

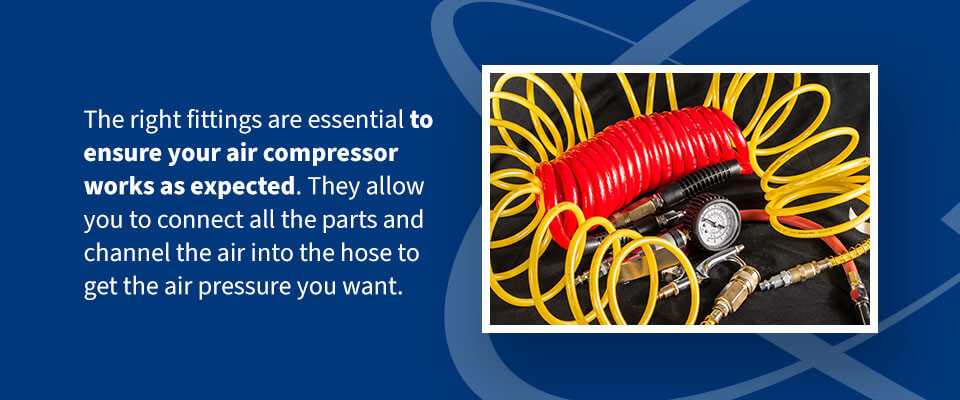

The right fittings are essential to ensure your air compressor works as expected. They allow you to connect all the parts and channel the air into the hose to get the air pressure you want. Air hose fittings will also enable you to connect different types of fittings so you can use various tools.

You have nearly endless options available to you, such as using a nail gun, running power tools, restoring your wheels or painting your car. Having different fittings lets you get more use out of your air compressor and work on larger projects.

It’s wise to have a few fittings on hand as backups. They can easily get damaged or misplaced, so keeping a few spares will ensure you can complete your projects once you’ve started. Investing in the right fittings also ensures that your compressor runs more efficiently. Loose parts can cause air to leak out, which consumes more energy.

What Is the Difference Between Male and Female Fittings?

Two components make up an air compressor fitting — a male, the plug, and a female, the socket. Typically, the female components connect to the air hose end — the male fitting or plug links to the tool. You can easily tell the difference between the two by looking at the end. The thread on the male fitting is visible, while the female thread is hidden inside the base, allowing it to connect to the male fitting perfectly.

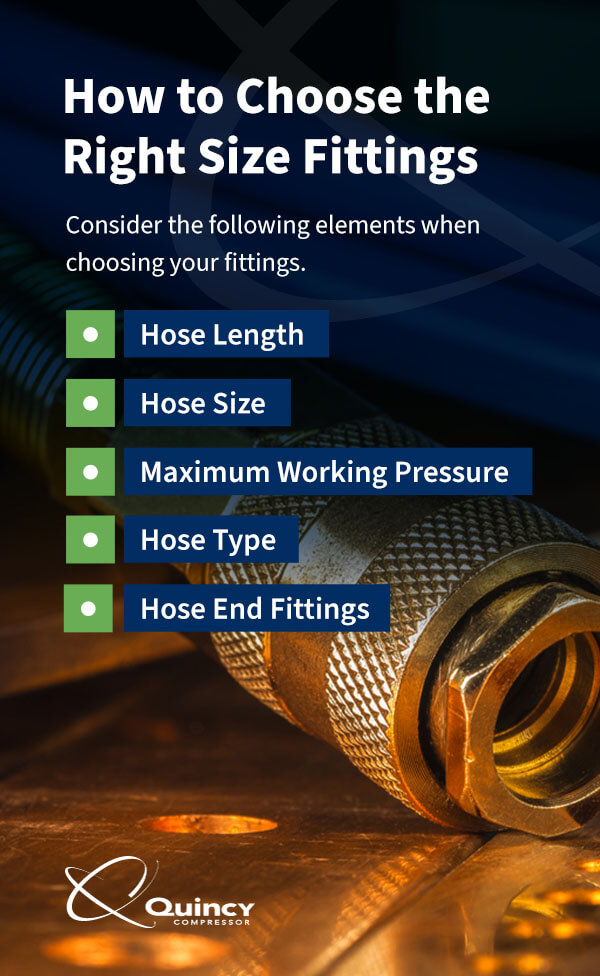

How to Choose the Right Size Fittings

When choosing the air compressor hose and fittings, there are several factors to consider. You’ll need to look at the size and type of air compressor and choose fittings with the same thread size. Also, consider your type of project and the performance you need. For example, for heavy-duty use, pick durable materials like brass or stainless steel for long-lasting performance.

Consider the following elements when choosing your fittings.

Hose Length

The correct hose length is essential to work comfortably. Consider the distance you need between the air compressor and your tools before choosing a hose. Hoses come in various lengths to ensure optimal performance when working on projects. Ensure your hose can also handle the maximum air pressure and flow rate. With this knowledge, you can decide on a suitable hose length made from durable materials.

Hose Size

It’s important to find the right size hose for your type of tool. A tool’s cubic feet per minute (CFM) determines the size of the hose you need. Larger tools, such as a spray gun, will require a larger hose with a wider diameter to allow for adequate airflow. A smaller tool, such as a nail gun, will work well with a smaller hose.

The wrong hose can damage your tool or result in subpar performance. Make sure you select the right hose based on the specifications of your tool and how you’ll use it.

Maximum Working Pressure

The fittings you choose must be able to handle the maximum working pressure of your tools. Check the manufacturer specifications for the tool’s maximum air pressure and ensure your fittings match the highest required air pressure.

When fittings have a low PSI compared to the tools, it can cause leaks and other defects in the system. Choosing quality, durable materials that can withstand the pressure instead of cheaper fittings will also prevent damage and potential harm to yourself.

Hose Type

When it comes to the type of hose, there are two main options — standard and coiled. Standard hoses are made of rubber and are very durable. Their design also makes them heavier and less flexible than the coiled variety. If you are working on a project requiring you to move your air compressor, consider a coiled, easily portable hose.

Hose End Fittings

There are a variety of hose end fittings to choose from — connectors, couplers and plugs. When you select your fitting, think about the application, working pressure and airflow requirements. The fittings must be compatible with your specific air compressors and the tools you’ll use. Pick connectors and fittings that best suit how you will use your compressor.

When to Replace Your Hose

Inspect your hose regularly to check for signs of abrasion or defects. If you notice any signs of wear, change your hose so you can keep using your system efficiently and safely. You can check for defects in your hose by evaluating its compatibility with your air compressor setup’s specs, such as tank size, cubic feet per minute delivery rate and horsepower rating.

Contact Quincy Compressor With Questions

Choosing the right fittings can be as important as selecting an air compressor. The right fittings ensure your system maintains the air pressure you need for your application. The team at Quincy Compressor is here to help you choose the right fittings for your system. Our air experts can answer your questions and help you find the equipment you need to keep your air compressor at its best.

Browse our products today and contact us with any questions!