When you need an air compressor for your operations, you have a choice to make — will you buy new or used? This comes after deciding the specific type of compressor you need, from rotary screw to reciprocating, so making another decision may be overwhelming. There are plenty of pros and cons for either type of air compressor, and you have many things to factor into your choice.

When buying a new versus used air compressor, which one is best? We’ll outline the differences as well as the advantages and disadvantages below to help you make your choice.

Difference Between New vs. Used Air Compressors

Before you even learn the difference between used and new air compressors, you may wonder if you can purchase used air compressors. The answer is yes. Plenty of industries use air compressors for various work tasks. As a result, there’s quite the market for both new and used air compressors. The difference is simple — companies or individuals have previously employed used air compressors in their work, while new ones have never been used before.

Used air compressors may come from companies that have decided to upgrade their system. They might also come from businesses that have downsized their equipment needs. Ideally, you’ll find a used air compressor that someone didn’t use often but maintained well.

Depending on who you purchase used equipment from, you may receive information from the past owner. You could discover how well they maintained the system, how long they had it for and what issues they had, if any. Sellers could also assess the equipment and either make repairs or advise you on any maintenance or replacements the air compressor needs. All that will depend on who you shop with and if the information is available from the previous owner.

When you buy a new air compressor, you’ll have access to all the specs you’d expect to receive with a new purchase. You get a current product that manufacturers back with decades of research and development. No one owned it before, so there’s no history of problems or repairs to look into.

No matter which option you shop for, you’ll likely find the type of air compressor you need for your operations. It just depends on current availability and demand. The main differences come with the pros and cons of new versus used air compressors.

New Air Compressors

With the right budget and a need for a quality machine, a new air compressor can guarantee you get the equipment you want. Compare the pros and cons of purchasing a new air compressor to see if it’d be the right choice for your operations.

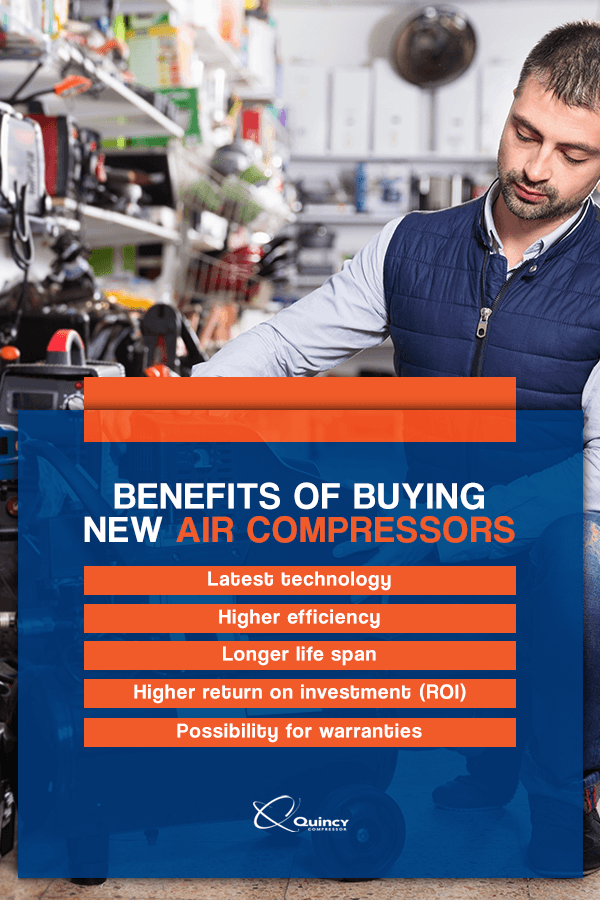

Benefits of Buying New Air Compressors

Purchasing a new air compressor comes with various advantages, especially when you compare it to getting a secondhand one. As long as your operations use the new equipment often, you’ll get these benefits of buying new air compressors:

- Latest technology: New air compressors use the latest technology to make your operations smoother. You can cut down on lead times and have more flexibility or consistency when you use an air compressor with the newest technology.

- Higher efficiency: A new air compressor may use power more efficiently than a used option. New machinery won’t have initial damage or required maintenance, which used equipment could have. Leaks, clogged air filters, incorrect pressure readings and other issues all impact an air compressor’s efficiency. You most likely won’t have a problem with those components in a new system.

- Longer life span: A used piece of equipment can have years taken off its life span, depending on how long the previous owner used it. A new machine has never been used, so you get a longer life span. You can further extend your air compressor’s life span by following maintenance tips and getting an air compressor audit, which helps protect your investment.

- Higher return on investment (ROI): As you decide which system will work for you, you’ll wonder which has the best ROI between used or new air compressors. You’ll get the most value from a new unit, thanks to its longer life span and quality components. A new air compressor is cost-effective because it will have better energy efficiency, and you likely won’t need to replace or repair components right away. A new air compressor also adds to your business’ equity, which is beneficial if you ever want to expand or borrow funds. To ensure you maintain that ROI, conduct regular maintenance and audits.

- Possibility for warranties: Depending on which equipment you purchase and where you buy it from, you could get a warranty. A warranty helps ensure you have little to no costs if your air compressor needs repairs or replacements. If there are any defects with your brand new equipment, a warranty may cover replacements then, as well. Look into the specific terms of your warranty to understand your coverage better, and check for what it covers and how long it lasts.

Disadvantages of Buying New Air Compressors

The primary disadvantage of buying a new air compressor is its cost. You’ll probably pay significantly more for a new system compared to a used one. But that’s because you’re paying for all the benefits of buying new air compressors. You get the latest technology, excellent warranty coverage and better efficiency. The machine also doesn’t have a history, unlike used options. If you can afford the cost of buying a new air compressor, it may be worth it in favor of all the advantages you get.

Used Air Compressors

If you purchase a used air compressor, you have to rely on the previous owner to have maintained it. With proper prior maintenance and a trustworthy seller, you could get a quality secondhand air compressor that suits your needs. Still, the machine will have its pros and cons. Evaluate the benefits and drawbacks of purchasing a used air compressor to see if it’d be right for you.

Benefits of Buying Used Air Compressors

To see if a used air compressor would be right for you, first consider the advantages. Compared to a brand new machine, you’ll get these benefits of buying used air compressors:

- Lower cost: The most appealing benefit of used equipment is a lower price. In some cases, you can purchase multiple used air compressors for the same price you could get for one piece of new equipment. Don’t let a lower price tag be the only deciding factor, though. New equipment comes with benefits that used machinery doesn’t, which validates a higher price tag.

- No initial depreciation: When you buy any sort of new machinery or equipment, its value immediately depreciates. You won’t have that problem with used equipment. It comes at an initial lower cost, and since someone has used it before, it has already gone through its initial depreciation.

- Quality refurbishments: Depending on the manufacturer and seller, you might get a high-quality refurbished machine. Components may be new yet compatible with the used air compressor, which would give you a more efficient and long-lasting system. Not every secondhand air compressor will have this level of care, though, so be sure to look into the specs if you buy a used machine.

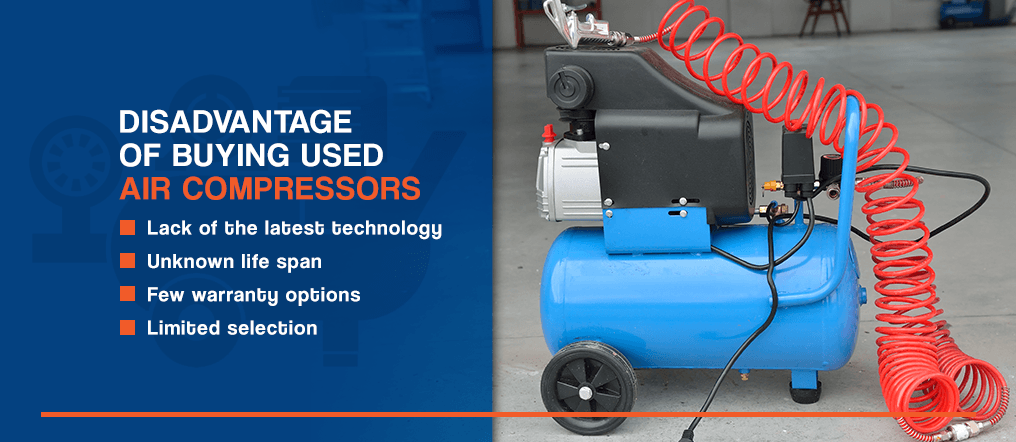

Disadvantages of Buying Used Air Compressors

Of course, when it comes to purchasing used equipment, you get what you pay for. A trustworthy manufacturer and seller will help eliminate some concerns you’ll have about the process. Still, with the advantages of a lower price come these potential disadvantages:

- Lack of the latest technology: Buying used means you’re getting a machine that probably wasn’t made in recent years. You’d have to sacrifice using the latest air compressor technology in favor of the benefits of buying used air compressors. Not having the latest technology could mean anything from getting equipment that’s less efficient to achieving a slower production and turnaround time than you would with a new system.

- Unknown life span: When you buy a new machine, you’re guaranteed an estimated life span. When you buy used equipment, it’s hard to know how long the air compressor will last. To combat this, shop with a trusted seller. They’ll provide as much information as possible with a detailed record, if one is available. That record can include information like how well the previous owner maintained the machine and how long they had it. Once you own it, you can get regular audits and maintain it well to sustain its life span.

- Few warranty options: You may not have as many options for equipment protection with a used system. If something happens to your machinery, you may incur higher costs to make repairs or replacements. This means that, while the initial cost is lower for used equipment, you may end up paying more not long after purchasing your secondhand machinery. You could find used equipment with available or extended warranties, but that will depend on the retailer and machinery.

- Limited selection: When you buy a used air compressor, you’re limited in your options. You can essentially pick from whatever stock of used equipment a seller happens to have at a given moment. If you’re looking for a particular model, you may need to wait or shop around. If you do want a used air compressor, consider focusing on the specs you need for your job instead of a particular make or model.

Which Option Is Best for You?

With the advantages and disadvantages of both air compressor buying options in mind, you’ll have to decide which will work for your operations. Perhaps reviewing the pros and cons of new versus used air compressors didn’t make your decision any easier. In that case, you should evaluate your unique needs and concerns. Determine whether you should purchase a new or used system by considering:

- Your initial budget: Your biggest concern will be your budget for the equipment’s initial expenses. While a new unit will almost always cost more than a used one, you should also factor in the cost of replacement parts and repairs a used system might need in the short term.

- Your budget down the line: If you have an estimate of your long-term budget, incorporate that into your decision. You may be able to afford a higher price tag now, but a used unit could cause financial trouble if your budget ever tightens. Remember that a new machine offers higher efficiency and a longer life span, potentially lowering power and maintenance costs.

- The amount of air and pressure you need: Consider your operations as you select an air compressor. Don’t compromise on your needs based on the price or advantages of one choice over another. If you need more air at higher pressures, you may consider an option with a large storage tank, which you could find in either used or new varieties.

- The tools you use: In general, you can operate pneumatic tools more consistently with a large compressor. If you need air purity or a steady stream of lightly pressurized air, consider a smaller machine. You’ll find either of these types available in new and used equipment selections, so remember not to compromise on your operational demands.

- How often you’ll use an air compressor: Perhaps for your operations, you use an air compressor multiple times throughout the day. In that case, you may want a new machine that will last longer and provide better energy efficiency. If you don’t often use an air compressor for worksite tasks, a used one could be a more cost-effective option for you.

Overall, you may find it’s best to invest in a new air compressor. Of course, the decision is up to you, and you won’t want to spend more than your means to get new equipment. Consider all the factors above, and if you’re having trouble deciding, consult with experienced professionals.

Shop Quincy Compressor’s New and Used Equipment

Whether you want to get new or used air compressors for your operations, Quincy Compressor has what you need. If you still can’t decide, our professional and knowledgeable air experts will be happy to help you pick the most fitting type for your operations. Whatever you select, you’ll enjoy our uncompromising reliability and performance, no matter your application.

From compressors to parts and service, everything at Quincy Compressor will surely give you the solutions you need. We also offer industry-leading warranty protection and extended warranty plans for various products.

Contact Quincy Compressor today for more information about our air compressors and other equipment.