Multi-Stage Compressors

Reciprocating/piston compressors use a cylinder to force air into a chamber, where it is compressed. The simplest compressor designs feature a single–cylinder/chamber arrangement. While straightforward, this setup is limited in its efficiency and capacity for delivering high volumes of pressurized air.

That’s where multi-stage compressors come in. By increasing the number of cylinder stages, these machines work more effectively and can handle more tools at once.

How Multi-Stage Compressors Work

Multi-stage compressors feature two or more piston cylinders, each of a different diameter. After the first compression stage, air passes through a heat exchanger, where it is cooled before arriving at the second cylinder. Cooling the air reduces the work needed to compress it during the second or third stages.

In a two-stage compressor, the air passes through two chambers total. In the second chamber, it is pressurized to the required extent. In a three-stage compressor, an additional cycle of compression and cooling occurs before this.

What Is a 2-Stage Air Compressor?

A two-stage air compressor is the most basic multi-stage compressor. Partially compressed air undergoes a cooling cycle before passing through another compression chamber where the air reaches the required pressure.

What Is a 3-Stage Air Compressor?

A three-stage air compressor is a multi-stage compressor with three separate chambers. Air moves through a first compression stage and then passes through two heat exchangers and two additional chambers. The three-stage compressor provides the most consistent power output and can operate for extended periods.

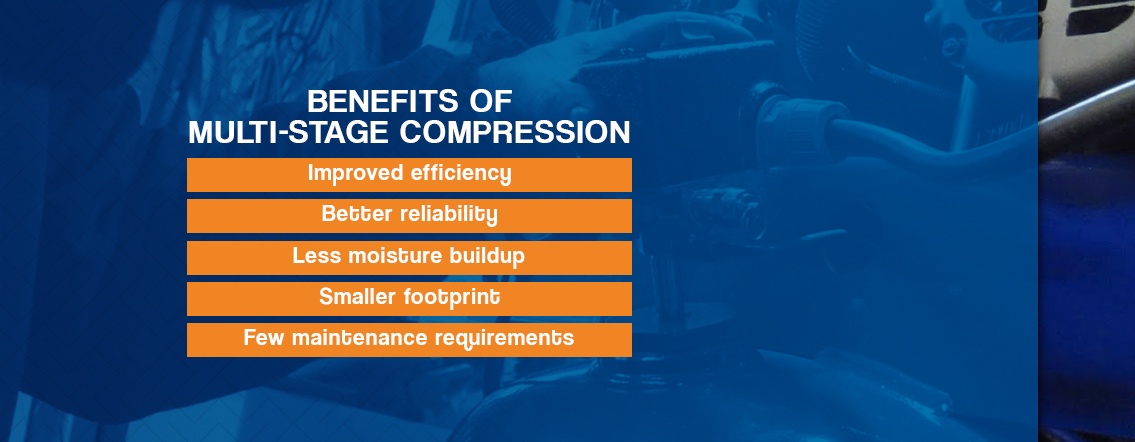

Benefits of Multi-Stage Compression

Both single– and multi-stage compressors have their benefits. The right one for your application will depend on a number of factors. Specific advantages of a three- or two-stage compressor design include:

- Improved efficiency: Two-stage compressors perform less work to compress air to a given pressure, which means your operating costs are lower.

- Better reliability: The intercooling stage of two-stage compression creates less chance of overheating, which in turn means more uptime and better productivity.

- Less moisture buildup: Cooler air has a lower moisture content. Moisture in compressed air can lead to equipment failure and premature wear. Using a two- or three-stage compressor can potentially save you from having to purchase a separate air dryer.

- Smaller footprint: For heavy-duty applications, multi-stage compressors deliver greater air pressure (PSI) at higher capacities (CFM) than single-stage machines of comparable size.

- Few maintenance requirements: Thanks to smaller components and cooler temperatures, wearable components don’t wear out as quickly. As a result, recommended service intervals are longer.

Cons of a Multi-Stage Compressor

While multi-stage compressors have numerous pros, some cons to consider are:

- Size: Multi-stage compressors are often larger and heavier than single-stage systems. If you choose a two- or three-stage compressor, you should ensure you have enough storage space in your facility.

- Maintenance: Because multi-stage compressors have additional chambers and heat exchangers, maintenance can be more demanding and involve the replacement of larger numbers of wear parts.

- Cost: Multi-stage compressors are more expensive than single-stage compressors.

2- vs. 3-Stage Air Compressors

If you need an air compressor for demanding work like auto repair or manufacturing, investing in a two- or three-stage air compressor is necessary to ensure your unit produces an adequate supply of air for your tools or machinery. While both two- and three-stage compressors provide reliable air output, there are instances in which one will work better than the other.

Two-stage systems are smaller and can produce high-pressure air while taking up the same space as a single-stage system, though they can’t match the output capability of a three-stage model. The latter will serve you better if space isn’t a concern and your application requires greater efficiency and higher air pressure.

Applications

Clearly, there are benefits to selecting a multi-stage machine. However, their higher cost means they are not necessarily the right choice for every application. Typically, single-stage compressors are best for lower pressure, light-duty, periodic use applications. Two- or three-stage air compressors, on the other hand, offer more efficiency and reliability for continuous use applications, such as manufacturing and auto repair.

Many reciprocating compressors come in both single- and two-stage options. If you’ve already selected a particular machine, you may be wondering whether you need a single- or multi-stage version. Here are six things to consider when choosing an air compressor to decide if a multi-stage system is right for your application:

- Pressure required: Before considering anything else, you can know for sure you need a two- or three-stage compressor if you need to produce high pressure. Because air is compressed in two or more steps, multi-stage compressors can deliver higher pressures. Typically, any pressure above 100 PSIG will demand a multi-stage compressor for the most efficiency.

- Volume of air required: An industrial multi-stage air compressor can pressurize more cubic feet of air per minute (CFM) than a single-stage compressor. Since most compressors take some downtime between pressure cycles, a higher volume produced per cycle can increase productivity. Machinery and air tools used for significant lengths of time will both require more air.

- Need for temperature control: Multi-stage compressors can regulate air temperature. Because they cool air as it passes between each chamber, the output air has a lower temperature. When heat can damage or reduce the efficiency of your air-powered equipment, choose a multi-stage compressor.

- Need for oil-free applications: Intercooling, which is used in most multi-stage compressors, it increases the moisture in the air. This moisture can mix with the oil in an oil-flooded compressor and cause issues with the machinery. So, most oil-free compressor systems are dual-stage.

- Space you have: The smallest single-stage air compressor will take up less room than the smallest dual-stage air compressor. For a DIY or contracting project, a single-stage air compressor may be lighter and more portable. When it comes to larger air compressors, a two-stage compressor will have a higher output than a single-stage compressor of the same size. So, for industrial applications, a multi-stage compressor will save space.

- Initial cost versus lifetime cost: The price of air compressing equipment is only 12% of the total cost of producing compressed air. So, while a single-stage compressor can be more affordable to buy, it’s critical to consider the lifetime cost, too. Most of the cost of compressed air comes from the electricity consumed. In this case, two- and three-stage compressors have the advantage because cool air compresses with less mechanical work. For small applications, the lower initial cost may outweigh the benefits of an efficient design. For larger applications, the lifetime cost of the machine is paramount.

Multi-Stage Machines From Quincy Compressor

Quincy Compressor has been a leading compressor manufacturer for nearly 100 years. We carry a complete range of products, including two- and three-stage air compressors designed for heavy-duty industrial use. Our products incorporate advanced technology to improve efficiency, reduce noise and keep maintenance requirements to a minimum. The best warranty programs in the business back all of our products, and we offer extended coverage on certain components for 10 years or more.

Our flagship product, the QR-25, is available in a 5 HP, 2-stage air compressor configuration. We also sell rotary screw and three-stage reciprocating machines. To learn more, check out our Resources page for more background on the technology and how it works.

To find an authorized dealer near you, please use our sales and service locator.

Last Updated on March 11, 2022 at 8:45 am