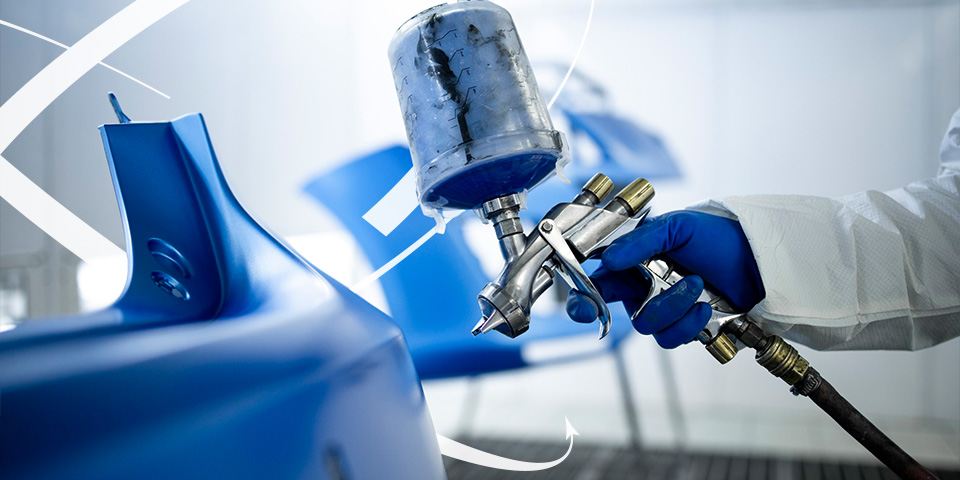

Paint shops rely on various tools and equipment to consistently deliver exceptional results. Among these, the air compressor stands out as one of the most essential components. Choosing the right air compressor for paint shops is a critical decision that can significantly impact the efficiency, quality and productivity of your operations. In this guide, we’ll explore the key factors to consider when selecting an air compressor for your paint shop, ensuring you make an informed choice tailored to your specific requirements.

Types of Paint Jobs

Painting is one of the critical uses of air compressors in auto repair and maintenance. Before diving into the specifics of air compressor selection, it’s essential to understand the different types of paint jobs that your paint shop can do:

- Automotive painting: Automotive painting involves applying paint to vehicles, ranging from minor touch-ups to complete resprays. Painting and bodywork using air compressors is common in auto body shops.

- Industrial painting: Paint shops may also cater to industrial clients, such as painting machinery, equipment and structures. These projects often require higher air pressure and volume compared to automotive painting.

- Touch-up work: Smaller paint shops may focus on minor repairs and touch-ups, which generally require less air than full paint jobs.

Understanding the nature of your paint shop’s work will help you determine the specific requirements for your paint shop air compressor.

Factors to Consider When Selecting an Air Compressor for Painting

When choosing the best air compressor for painting, there are several key factors to consider, including:

Compressor Sizing

Sizing is one of the most important considerations when selecting an air compressor for your paint shop. You’ll need to determine the minimum size air compressor for painting a car or other objects based on the air requirements of your paint guns and other tools. Generally, most paint guns require a minimum of 10 to 15 cubic feet per minute (CFM) at 90 pounds per square inch (psi) to operate effectively. However, the specific air compressor for your paint shop may vary depending on the paint gun type and the project size.

Choose an air compressor with a higher CFM rating than your most demanding tool to ensure sufficient air supply. This higher CFM rating will allow for a margin of safety and ensure your compressor can keep up with your shop’s needs.

Air Pressure Requirements

You’ll also need to consider the psi air compressor requirements for your paint guns. Most paint guns operate at around 20 to 30 psi, but some may require higher pressures of 40 to 60 psi or more. It’s essential to check the specifications of your paint guns and choose an air compressor that can deliver the necessary pressure.

When determining the psi considerations for different types of painting, keep in mind that automotive painting generally requires lower pressures than industrial painting. However, it’s always best to be cautious and choose a compressor with a higher psi rating to accommodate any future needs.

Energy Efficiency

Running an air compressor can be a significant expense for paint shops, so it’s essential to consider energy efficiency when making your selection. Look for compressors with high-efficiency motors and variable-speed drivers, which can help reduce energy consumption and lower operating costs.

Properly sizing your compressor and minimizing air leaks in your system can enhance energy efficiency, contributing to cost savings over time. By prioritizing energy efficiency, you can save money on your energy bills and reduce your shop’s environmental impact.

Air Quality

Clean, dry air is essential for achieving high-quality paint finishes. Moisture, oil and other contaminants in compressed air can lead to defects in the paint, such as bubbling, peeling and fish eyes. Consider models equipped with advanced filtration and moisture control systems to ensure you get the best air compressor for painting.

Filters help remove particulates, oil and other contaminants from the air. Moisture control systems, such as dryers and aftercoolers, reduce the humidity in the compressed air. Investing in high-quality filtration and moisture control ensures that your paint jobs are consistently flawless.

Frequency of Use

The frequency and intensity of your paint shop’s operations will also influence your choice of air compressor. If your paint shop operates daily, you’ll need a durable, reliable air compressor that can withstand constant use. Oil-injected rotary screw compressors are well-suited for daily paint jobs, as they can run continuously without overheating.

A smaller, less expensive compressor may suffice for paint shops that operate only occasionally. Piston compressors are a good choice for intermittent use, as they can provide sufficient air for smaller paint jobs.

If your paint shop handles a high volume of work, you may need a larger, more powerful air compressor to keep up with demand. Two-stage compressors are ideal for high-volume operations, delivering higher air pressures and volumes than single-stage compressors. By assessing your shop’s frequency and intensity of use, you can select an air compressor that meets specific needs and budget.

How to Set up an Air Compressor for Painting

Once you’ve chosen a suitable air compressor for your paint shop, you must set it up correctly to ensure optimal performance and longevity. Here are some steps to follow:

- Choose a suitable location for your compressor, away from extreme temperatures, moisture and dust.

- Install the necessary piping and fittings to connect your compressor to your paint guns and other tools.

- Set up a moisture control system, such as a dryer or aftercooler, to remove humidity from the compressed air.

- Install filters to remove particulates, oil and other contaminants from the air.

- Adjust the pressure regulator to ensure your paint guns receive the correct air pressure.

Following safety guidelines when setting up and operating your air compressor is vital. Ensure your compressor is properly grounded to prevent electric shock. When operating the compressor, wear appropriate personal protective equipment (PPE), such as safety glasses and hearing protection.

You should never operate the compressor in a confined space or near flammable materials. Regularly inspect the compressor and its components for signs of wear, damage or leaks. Follow the manufacturer’s guidelines for safe operation and maintenance of the compressor.

How to Maintain an Air Compressor

Regular maintenance is crucial to ensuring the longevity and performance of your paint shop air compressor. Some routine maintenance tasks include:

- Checking and changing the oil regularly

- Cleaning or replacing air filters

- Draining moisture from the tank

- Inspecting and tightening belts and bolts

- Checking for leaks in the piping and fittings

If you encounter any issues with your air compressor, such as reduced air output or strange noises, troubleshoot them promptly. Common problems include clogged filters, leaking valves and worn-out seals. Addressing these issues early can prevent more serious damage and keep your compressor running smoothly.

Unlock Your Paint Shop’s Potential With Quincy Compressor

Selecting the best air compressor for your paint shop is a critical decision that directly impacts your productivity, quality and bottom line. By carefully evaluating your shop’s specific needs and considering factors such as compressor sizing, energy efficiency, air quality and frequency of use, you can make an informed choice to help your business thrive.

For expert guidance and top-tier compressor products, look no further than Quincy Compressor. With nearly a century of experience and a dedicated network of professional and knowledgeable air experts, we’re here to help you unleash your paint shop’s full potential. Contact us today to discover reliable, efficient and high-performance compressor products.