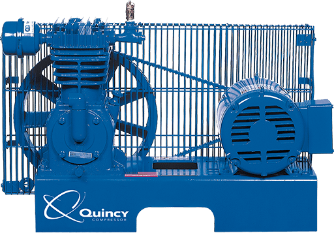

- 1-25 hp

- 3-95 acfm, 20-500 psig intermittent

- Single & Two Stage

- Cast iron full pressure lubricated

- 5-Year limited warranty

- 5-15 hp

- 17-51 acfm, 175 psig maximum

- Two Stage

- Cast iron splash lubricated

- 10-40 hp

- 360 or 580 psi

- Full Feature available with aftercooler and Q-control

- 5 to 15 HP

- 175 PSI Working pressure

- Oil filter and pressure gauge

- Fully pressure lubricated

- 0.5-20hp

- 4-88 acfm, up to 100 psig service

- Single & Two Stage

- 2 ppm carry over factory certified

- 4 to 12.4 acfm

- 110 to 145 psi

- Single Stage

Benefits of a Reciprocating Air Compressor

Some of the critical benefits of a reciprocating air compressor are:

- High pressure and power: Reciprocating compressors can push out high pressure and energy, even though they are compact.

- Low maintenance costs: These compressors have fewer moving parts than others, which leads to less wear and tear and part replacement.

- Improved efficiency: Reciprocating compressors can be used intermittently and do not need to run continuously. They produce high power at low energy levels and can help lower your outputs. They are best used when turned on and off frequently.

- Longer product life: As these compressors do not run repeatedly, they are less likely to need repairs. You can get more time out of your compressor.

- Compact design: These compressors are smaller than other styles, making them easy to transport and place closer to the work site. If you work in oil and gas, a portable compressor can help on multiple sites.

Quincy Compressor carries several different reciprocating air compressors for any industry. Browse our inventory of air compressors to discover which one is best for you.

How Reciprocating Air Compressors Work

Compressors decrease the amount of space air takes up by compacting it. A reciprocating compressor is a positive-displacement air compressor that uses a crankshaft-powered piston and cylinders. Our piston air compressors use either a single- or two-stage process to compress air.

Compressing air decreases its volume and increases its density without changing it to liquid. Here is how a reciprocating air compressor works:

- Gas enters the cylinder through the intake valve.

- The piston pulls away from the intake valve and allows the gas to pass into the cylinders.

- The crankshaft powers the piston, which compresses the gas in one stroke of about 120 pounds per square inch (psi) of pressure.

- In two-stage compressors, air travels to a second cylinder for another round of compression. A second piston compresses the gas at a pressure rate of 175 psi.

- Once complete, the compressed air is sent to a storage tank for use.

Reciprocating air compressors are compact options workers can apply to natural gas processing and delivery and oil refining. These air compressors work across industries to give you powerful compression.

Your Local Quincy Distributor Offers a Wide Selection of Reciprocating Air Compressor Parts

Your Quincy Compressor dealer is your one-stop source for all of the reciprocating air compressor parts you need to keep your unit up and running, whether you need fluid for maintenance, an air compressor piston, pump, belt or other vital part or component

Ask your dealer about our tough, tougher and toughest piston air compressor options.

Ready to learn more about properly maintaining your reciprocating air compressor? Follow the link to learn more about oil and maintenance.

Click here to find the right air compressor for your industry-specific application.