Rotary vane vacuum pumps are ideally suited for a wide range of low and medium vacuum applications such as general and chemical laboratory, analytics, freeze drying, process engineering and more. A rotary vane pump works via positive displacement, which is when volumes of air or gas are confined within a closed space and are compressed when the space is mechanically reduced.

Rotary Vane Vacuum Pump Components

A typical rotary vacuum pump is comprised of a housing, a rotor and a series of radially moving vanes, which come in dry-running or lubricated versions (the latter are the most commonly used in the majority of industrial applications). The rotor is generally the only continuously moving vane vacuum pump part. There’s also a working chamber inside the housing, which is divided into two separate compartments by the rotor and vanes. Many vane vacuum pumps also include an inlet valve as a safety feature.

Rotary vane vacuum pumps are available in single-stage and two-stage versions. The stages refer to the number of times that compression actually occurs. Two-stage pumps are also able to attain a lower pressure than single-stage pumps, due to the fact that gas is only admitted during the high pressure stage.

Testimonials

Rotary Vacuum Pump Operating Principle

Here’s a brief overview of how a rotary vane vacuum pump works: As the pump’s rotors turn, it results in the creation of centrifugal force and the related development of compression cells. Gas is forced to flow into the suction chamber, where it is then sealed by a vane. The gas is compressed until atmospheric pressures force the outlet valve to open. With an oil-lubricated vane vacuum pump, the opening of the outlet valve enables oil to enter the suction chamber to lubricate the vanes and also seal them against the housing.

Rotary Vane Vacuum Pump Benefits

Most rotary vane vacuum pumps are able to handle thin liquids at relative high pressure. The extension of the vanes during operation helps to compensate for wear. An oil-lubricated rotary vacuum pump can also run dry for short periods of time, which can reduce overall oil consumption and cost. Dry-running pumps in particular are extremely cost-effective to own and operate and are known for being very eco-friendly.

Vane Vacuum Pump Maintenance

A rotary vane vacuum pump is relatively easy to maintain. The vanes will tend to wear down over time — they should be replaced when their length becomes one fourth of an inch shorter than when brand-new. You should also replace the bearings if you notice any play in them. If a new bearing does not fit tightly against the shaft, which is a fairly common issue with vane pump bearing replacement, the shaft likely needs to be welded and machined. Worn seals should be repaired as quickly as possible, as this is the leading cause of vane vacuum pump failure.

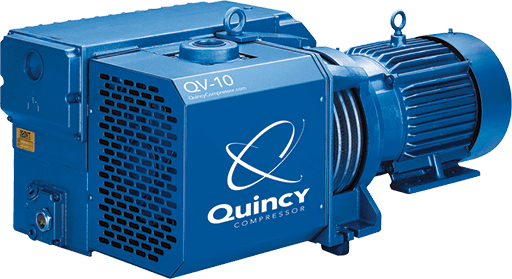

Contact Quincy Compressor or the authorized Quincy distributor in your local area to learn more about rotary vacuum pumps, their benefits and their applications.

Learn more about finding the right rotary vane vacuum pump parts.

Learn about industrial vacuum pumps.