An air compressor is a device — consisting primarily of a piston and cylinder — that powers an array of tools by means of pressurized air for various applications. In the fields of construction, auto maintenance, furniture assembly and woodwork, the majority of applications rely on compressed air for speed and precision in everything from drilling, bolting, and nailing to sanding, greasing and painting.

The process of compressing air is initiated by the suction of air through the inlet valve. Once trapped, the air is compressed by the piston and then passed into a tank where the air gets pressurized. In its newly pressurized state, the air serves as an energy source for any given tool connected to the compressor. The process is measured in two variables:

- Cubic feet per minute (CFM): The rate that air moves through the compressor.

- Pounds per square inch (PSI): The amount of pressure created during compression.

In particular, air compressors power pneumatic tools. These power tools, also known as air tools, run on compressed air instead of electricity. Learn more about pneumatic tools and common types powered by air compressors.

Contact Us Learn More Find a Dealer Near You

What Are Pneumatic Tools?

Pneumatic tools operate on air power rather than batteries or electricity. Air compressors power these tools with highly pressurized air. You mount the tool to an air compressor with a hose and regulator, and the regulator allows you to set the air pressure to the necessary amount for operation. Then, compressed air runs through the regulator and hose directly into the tool.

Pneumatic motors convert energy from compressed air into mechanical action. Tools can have either linear or rotary setups, which determine the airflow’s movements to the motor. Each tool requires specific airflow and pressure requirements for operation. For instance, pneumatic nail guns are linear-action tools, which move air in a straightforward way. Pneumatic drills, on the other hand, have turbine or gear motors that allow the tools to rotate.

Consistent air streams at the right pressure allow pneumatic tools to run continuously. Various tool types need different air volumes, and corresponding air tanks hold the necessary amount. For example, paint sprayers require large quantities of air at low pressures, but nail guns need smaller volumes at higher pressures.

Different air compressor types can meet the needs of various tools and working durations. You can find many pneumatic tools for various applications and industries, from heavy-duty industrial work to household chores.

Pneumatic Tools Powered by Air Compressors

Air compressors power many tool types for different industries and applications. Here are examples of pneumatic tools powered by these machines:

Drills

When it comes to woodworking and construction, few tasks require more precision than hole drilling. With just one slip of the arm, a hole could wind up crooked and the whole project becomes compromised. With an air–powered drill, a hole can be made in just a fraction of the time it would take when using an electric drill. You could make deep holes in boards of varying thickness, each within just a split second. Best of all, an air drill can even blow holes through metal, and it rarely overheats.

Drills require air pressures of an average of 3 to 6 CFM at 90 PSI.

Orbital Sanders

Sanding is one of the most exhausting tasks in woodworking. With each swipe, the grains of a sand block leave streaks along surfaces in one direction or another. An orbital sander solves this problem by moving varyingly in random, circular directions, all for an effect that prevents marks from forming in any one or two directions on a given surface.

Furthermore, an orbital sander can smooth out rough surfaces in just a tenth of the time it would take with a plain piece of sandpaper. Most importantly, an orbital sander does all the brisk motions. All you have to do is hold it above the surface and power on. There’s no exhausting wrist or arm strain.

Orbital sanders require air pressures of an average of 8 to 12.5 CFM at 90 PSI.

Socket Wrenches

In metal work, auto maintenance and construction, wrenches typically require a lot of arm and wrist movement. Equally as troublesome is the fact that nuts are hard, if not impossible at times, to manually remove from bolts once the effects of time, weather and the elements have welded things into place.

The socket wrench, or ratchet, has solved this dilemma by doing most of the turning for you, but a pneumatic socket wrench goes several steps further by doing the unbolting and rebolting faster and much more effectively. That means no awkward slip ups that strip the grooves and rarely a stubborn bolt that won’t come undone. Furthermore, a socket wrench can be fitted with various circumferences, so you don’t have to carry multiple wrenches for various–sized nuts.

Socket wrenches require air pressures of an average of 2.5 to 3.5 (1/4″), 4-4.5 (3/8″) CFM at 90 PSI.

Air Hammers

An air compressor can be used to power many different tools, and some of those tools can be affixed with various extensions. One such tool is the pneumatic air hammer, which by itself can be used to carve stone and cut up metal, both of which can be handy if you’re a sculpture or crafts person. The possibilities don’t stop there. An air hammer can also be affixed with a shock–absorber chisel — which separates shock absorbers — as well as these extension tools:

- Exhaust–pipe cutter

- Ball–joint separator

- Rubber–bushing splitter

Air hammers require air pressures of an average of 3-11 CFM at 90 PSI.

Brad Nailers

Regular nails of the hammer and nail variety have their place with various projects, but there are applications where the fat, flat heads of nails would be unbecoming. For household features such as basic and decorative trim, you need thinner, unassuming fasteners that won’t require large holes or potentially crack the delicate materials being applied. Brads are just the thing for projects such as these.

Brads go straight into the trimming and leave barely a trace to the naked eye. When a brad nailer is powered pneumatically, each brad applies in a split second.

Brad nailers require air pressures of an average of 0.3 CFM at 90 PSI.

Grease Guns

Grease makes it possible for machinery to move. In any given machine, the moving parts consist of metal pieces, none of which would work without grease because everything would be grinding against each other to the point of wear and corrosion.

Applying the right amount of grease on hard-to-reach machine parts takes precision and hand–eye coordination, but the whole process is easier with a pneumatic grease gun, which can apply grease instantly at just the right amount. An air–powered grease gun is an invaluable tool for lubricating engine parts.

Grease guns require air pressures of an average of 4 CFM at 90 PSI.

Angle Grinders

If there’s one material that’s meant to withstand all force, it’s metal. That said, there are times when metal itself needs to be trimmed, sawed or cut away. With an air–powered angle grinder, you can trim off edges or cut out shapes on sheets of metal, the one material that’s stronger than rocks or stones. For metalworking and construction, an angle grinder is a must-have tool. Angle grinders are also used sometimes in rescue missions, such as when victims are trapped in crashed vehicles where the doors are rendered immobile.

Angle grinders require air pressures of an average of 5 to 8 CFM at 90 PSI.

Hydraulic Riveters

The properties of metal are far different than wood or drywall. As such, structures consisting of metal panels require different fasteners than nuts, bolts or nails. Rivets are basically short metal pins that are used to join together metal plates. In pre-made holes, the rivet is pushed into place with a riveter tool, the most powerful of which is the air-powered kind that uses hydraulic oil.

Hydraulic riveters require air pressures of an average of 4 CFM at 90 PSI.

Speed Saws

The saw has been an essential cutting tool since the dawn of construction and furniture making, but compressed air has long since made the task of sawing materials a whole lot easier. With an air-powered saw, your arm is not required to physically swing up and down, back and forth in order to trim boards and 2x4s.

A pneumatic saw will not just give you cuts with fine edges and precision, the tool will do so in just a fraction of the time it would take to saw the old-fashioned way. Furthermore, since there’s no overexertion of the wrists and elbows, it’s much easier to maintain a straight line while sawing with an air–powered tool.

Speed saws require air pressures of an average of 5 CFM at 90 PSI.

Framing Nailers

For anyone with less-than-perfect hand-eye coordination, nailing things together can be troublesome. Sometimes you hit off-target and either bend the nail or damage the board. Other times the nail might refuse to go in all the way. Problems such as these are solved with a pneumatic nailer, which can send each nail in straight and all the way through, regardless of the thickness, all in a split second. Within a quarter of a minute, you could have all the nails applied up and down a given piece of furniture or wall application.

Framing nailers require air pressures of an average of 2.2 CFM at 90 PSI.

Needle Scalers

Wood is not the only surface that could be in need of sanding. You need a tool to cut through all the years of corrosion and buildup and reveal the original sleek surface on old steel panels that are encrusted with:

- Rust

- Soot

- Barnacles

On a needle scaler, a clutch of long, thick, powerful needles bristle away at thick paints and crusty residues that no sander could ever tackle.

Needle scalers require air pressures of an average of 8 to16 CFM at 90 PSI.

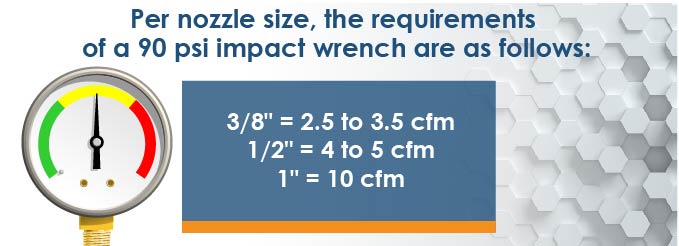

Impact Wrenches

Out of all the common fasteners, nuts are perhaps the most stubborn. In most applications, nuts are screwed on as tight as possible with the assumption they’ll never be unscrewed for any reason. This very problem has become its own industry in the tools trade.

Add in cycles of moisture and heat, and eventually a nut and bolt pair become inseparable. With an air–powered impact wrench, however, the nut has met its match. Not only will the wrench undo years of bonding, it will do so in seconds. A pneumatic impact wrench is perfect for car maintenance, whether you need to remove engine parts, lights, hubcaps or any other components that could be hard to unscrew manually.

Impact wrenches require air pressures of an average of 2.5-3.5 (3/8″), 4-5 (1/2″), 10 (1″) CFM at 90 PSI.

Die Grinders

When it comes to joining two panels of metal together, there’s nothing more problematic than mismatched hole sizes. A die grinder can be affixed with carbide bits of varying circumference, either pointed or round–tipped, that can be used for widening holes and filing edges on pieces of metal. A die grinder can also be used for honing curves and polishing edges on sheets and pieces of metal, as well as on wood parts.

Die grinders require air pressures of an average of 4 to 6 CFM at 90 PSI.

Shears

Metal isn’t made to be cut like paper, but sometimes it is necessary. With pneumatic shears, a blade cuts through sheet metal in much the same way an X–Acto knife slices paper.

Whether you wish to make a metal cutout for use in an art project or a piece of furniture, the seemingly impossible can indeed become possible with an air-powered, hand-operated shear. Each slice leaves behind a thin strip of spiraled metal “confetti,” which you can either discard or use as ornamentation.

Shears require air pressures of an average of 8 to 16 CFM at 90 PSI.

Tire Inflator With Gauge

Out on the open road, a car requires evenly inflated tires. However, what may look even to you could actually be a few pressure points off, which can mean a big difference to the axle alignment.

With a pneumatic tire inflator and gauge, you can pump your tires with the exact amount needed for uniform pressure along the fronts and backs. A pneumatic inflator will not only do the job quickly, it’ll also do all the pumping work. All you have to do is stick the tool into each tire nozzle and use the gauge to adjust pressure.

Blowers

Dust is a pesky nuisance when it comes to electronic and motorized equipment, and as everyone knows, machines attract dust like fabric draws moths. From engine parts to machinery, dust and debris can cluster up in places that are vital to key functions. As a result:

- Air flow gets blocked

- Circuitry gets smothered

- Components overheat, slow down or burn out

Dust can even accumulate in a lot of key places that can’t be reached with a manual brush, while other dust-encrusted areas could be too hot or have too much static for contact. For situations such as these, a pneumatic blower is an essential tool for clearing away dust and debris and restoring vital machinery.

Paint Sprayers

Among all the precision–based applications, few are as important when it comes to outer appearances as paint jobs. On vehicles, the slightest imperfection in a coat of paint could lead to complaints and poor reviews for the service shop in question.

In order to get perfect coats that are free of streaks, inconsistencies or brush strokes, compressed air is an absolute must. Most importantly, the compressed air application must be oil and moisture free. With today’s air compressors, perfect paint coats are easy to achieve with the hookup of optimal paint-spraying tools.

How to Safely Work With Pneumatic Tools

While pneumatic tools are extremely beneficial and offer more power than standard tools, they also present unique safety risks. The most prominent concern when working with pneumatic tools is the risk associated with highly pressurized air.

High-pressure air can easily propel objects at high velocities, potentially causing severe damage or injury. For example, if a drill attachment is unsecured, the high-pressure air could send it flying, creating an airborne hazard.

Because this risk exists, OSHA outlines various pneumatic power tool regulations to help ensure your safety when using these tools in the workplace. Whether you’re using pneumatic tools for work or jobs around the house, safety should be a priority.

Pneumatic Tool Safety Tips

These are a few general pneumatic tool safety tips to remember when working with any air tool:

- Wear appropriate PPE: You should wear personal protective equipment (PPE) when operating any power equipment, especially air tools. Pneumatic tools can be loud, especially in smaller spaces, so hearing protection is a necessity. Safety glasses are also a must, along with a dust mask to prevent yourself from inhaling dust and other debris when working. Gloves, a hard hat and safety boots are also recommended.

- Regularly inspect your tools: Inspect all pneumatic tools before use. Make sure connections are secure and that nothing is wrong with the setup. Regularly check tools and hoses for signs of wear, like holes or cuts. If you notice any issues, replace the tools immediately before further use.

- Follow the owner’s manual: Each tool should come with an owner’s manual that outlines how to use and care for your specific tool properly. Following the information in the manual, like the manufacturer’s rating, helps ensure you’re using the equipment safely.

- Designate specific areas for pneumatic tool use: You should communicate details about pneumatic tool use, including when and where you plan on using the tool. That way, others know to stay out of the way and can avoid a potentially hazardous situation. When you assign a specific area for pneumatic tool use, others can always be aware of the tool’s location and avoid the area.

Compressed Air Safety Tips

Because air compressors are the primary way to power pneumatic tools, it’s important to understand compressed air safety, too. Keep these tips in mind when running an air compressor with your pneumatic tools:

- Ensure compressed air is clean and dry: Moisture or debris in your air lines could damage your tools and affect their performance. For example, moisture in the lines of a paint sprayer results in inconsistencies in the paint job.

- Avoid placing objects on or against the air compressor: Air compressors require adequate airflow and venting to prevent overheating. Impeding the airflow can cause damage.

- Keep the air shut-off valve within reach: If an accident occurs, you need to turn the compressor off immediately.

Buy an Air Compressor to Power Pneumatic Tools

Air compressors can power a wide range of pneumatic tools. These efficient and compact machines meet the needs of many applications and industries. Professional-quality speed and precision outperform standard and manual equipment. Instead of using heavy, complex machinery, manufacturers use portable air compressors to power their tools.

If you are interested in learning more about pneumatic tools and buying an air compressor, explore the offerings at Quincy Compressor today. For a century, we have been a leading air compressor manufacturer for numerous industries and environments. See how we can assist you by visiting our sales and services page.

Contact Us Learn More Find a Dealer Near You

Last Updated on June 30, 2023 at 8:15 am